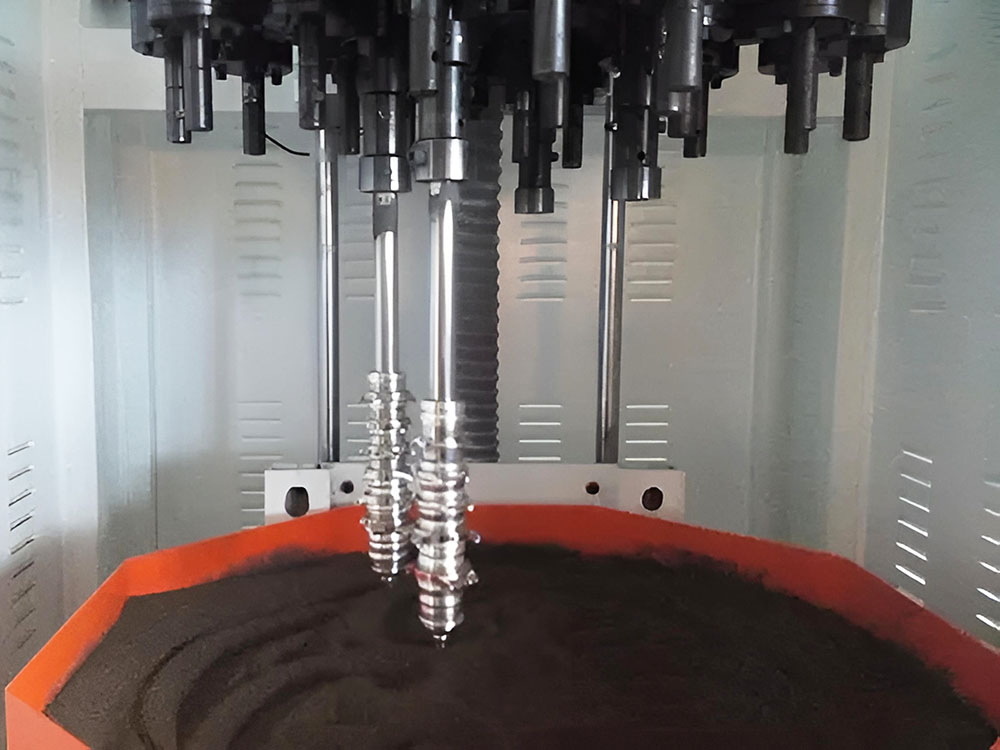

Technological development has been proven in the invention and innovation of many devices like the drag finishing machine. This is large-scale equipment used for polishing, grinding, and deburring surfaces to achieve a smooth and luxurious look. It uses intensive energy to work on these areas that are clamped onto it. The holder moves in a circular motion and at a high speed, pulling around the tub with the grinding media.

Table of Contents

- 1 What is a drag finishing machine?

- 2 How to Use a Drag Finishing Machine?

- 3 What Media (Consumable) Is Used on Drag Finishing Machine?

- 4 What are the Advantages of a Drag Finishing Machine?

- 5 Drag Finishing Machine Application

- 6 What are the Factors to Consider when Acquiring a Drag Finishing Machine?

- 7 Final Thoughts

What is a drag finishing machine?

Key Features

- Fast processing time, just a few minutes

- Has no part-on-part vibration

- Has two separate variable speed gear motors for workstations and carousel

- The sliding window saves space for easy loading and unloading.

- Rotating tubs for finer finishes.

- Practical motor positioning for high-vibration

- In-built cleaning and rinse feature.

- Capable of handling delicate, smooth, and enormous products.

How to Use a Drag Finishing Machine?

Step 1: Area preparation

The first is preparing the area you wish to work on by bringing the grinding essentials nearby and wearing the personal protective equipment. Ensure that any items that would cause accidents during the process are cleared. Another preparation technique involves ascertaining the grinding media is ready for the process.

Step 2: Positioning

Step two of drag finishing is positioning the essentials ready for the procedure. Put the machine in place, followed by the material you want to grind, guaranteeing they are well aligned. This prevents sudden falls of the materials or unsatisfactory results.

Step 3: Lubricate and reset

Before you start the procedure, it’s best to lubricate the machine. This eliminates the chances of uneven grinding due to the dryness of the device’s components. Proceed to reset the variables, which often include speed, pressure, or time for the best outcome. You can refer to the user manual for further guidance.

Step 4: Start grinding as you observe

You can start grinding the material as you observe the flow. Be keen to notice an uneven finish, leakages, or material displacement. If you do, you can pause the process to correct the defect accordingly. Drag finishing machines still require minimal supervision despite being automated.

Step 5: Finish and disassemble

After successfully finishing, stop the machine by pressing the right buttons on the control system. Continue to disassemble the components by removing the polished material from the work chambers. Unplug the machine, clean, and store it appropriately. Repeat the above procedure for finer results or on a different material.

What Media (Consumable) Is Used on Drag Finishing Machine?

- How many pieces do you want to polish?

- The hardness and shape.

- Size and desired final polish.

- The type of material you want to finish, i.e., abrasive or non-abrasive.

What are the Advantages of a Drag Finishing Machine?

- Saves time and money: These devices are cost-effective, cutting expenses and time consumed on manual finishing.

- Drag finishing machines are eco-friendly as they produce less noise, and some of their finishing media are recyclable, hence more sustainable.

- These devices have unmatched efficiency, especially on large-scale processes that are demanding to finish. The final results are just as imagined- stunning!

- Their ability to work on nearly all types of materials at a high speed makes them extra versatile.

- Drag finishing machines are automated, minimizing the need for full-time observation; therefore, attendants save more time handling other duties.

Drag Finishing Machine Application

As highlighted earlier, drag finishing machines are used in various sectors, such as:

Ceramic: Ceramic finishing media is used when working on ceramic components like utensils, pottery, and tiles. They get rid of undesired roughness to attain a smooth finish.

Plastic industry: Drag finishing machines are used to remove imperfections on plastic surfaces such as utensils and furniture.

Metal industry: Drag finishing machines are used to make fine surfaces on metallic components like shafts, edges, or metallic utensils.

Automotive engineering: Various automotive essentials, such as engine parts, covers, rims, or brakes, are finished using drag finishing machines for better quality and functionality.

Motor racing: Motor racing components like camshafts, pistons, gear wheels, and valves are generally smooth from the exceptional finishing by the drag finishing machine.

What are the Factors to Consider when Acquiring a Drag Finishing Machine?

- Maintenance needs: Ensure you go for the most affordable drag finishing machine regarding maintenance requirements. Some devices are highly maintained, hence more expensive in the long run.

- Quality should remain undebatable when acquiring a drag finishing machine for an extended lifespan and impressive finishes. Be sure to purchase from a respectable dealer or manufacturer.

- Workload: It’s important to get a machine that matches your standard workload. High-energy ones are best suited for large-scale finishes and vice versa.

- The type of material to be finished also influences the design of the finishing machine. For instance, it must have the appropriate media and capability to grind or polish the material easily.

Final Thoughts

It’s no lie that drag finishing machines are essential in many production processes. To achieve fine, quality, and good-looking products, you must consider what type of machine best fits your desired outcomes. The dealer or manufacturer also has a lot of influence on the device’s effectiveness.