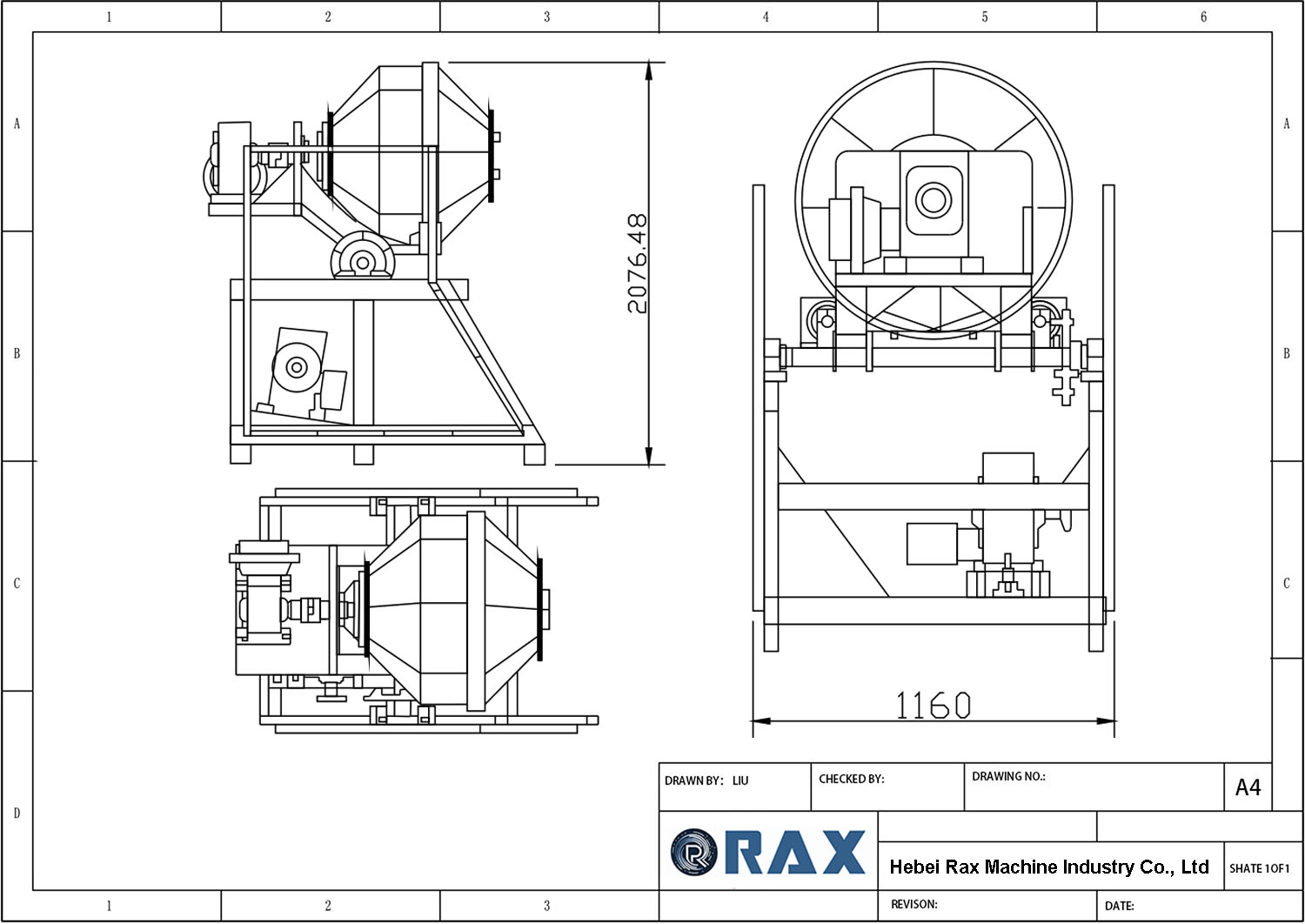

Tilting Barrel Finishing Machine

Tilting Barrel Finishing Machine, also called Tilt Rotary Drum Polishing Machine or Cannonball type Barrel Grinding Machine, efficiently finishes, deburrs and polishes different types of components and parts. It is particularly used for finishing large quantities of parts within a short time and attaining a consistent finish on irregularly shaped or complex parts.

The machine works by placing the parts inside the rotating barrel or drum together with media like polishing compounds, abrasive grit or other finishing materials. As the barrel rotates at high speeds, the media and parts rub and collide against each other, resulting in a desired surface finishing impact.

Made from no-seam vinyl plastisol, urethane lining or rubber and the unique safety enclosed housing, the machine guarantees durability and safety protection features. This makes it useful in applications involving wood, plastic, longish or delicate parts.