Also named Vortex Surface Finishing Machine or Eddy current polishing machine, the machine works at an ultra-high speed, therefore making it possible to finish massive products in a relatively short time compared to traditional vibratory finishing methods. The machine provides finishing of parts of different sizes, to give stunning results.

Now, if you are looking to buy a centrifugal disc finishing machine and you have doubts about whether it is the right choice for you, then this is the right place to be. We explain everything you need to know about the machine to help you make an informed buying decision.

Table of Contents

- 1 Function of the Centrifugal Disc Finishing Machine

- 2 How the Centrifugal Disc Finishing Machine Works

- 3 Key Features of the Centrifugal Disc Finishing Machine

- 4 The Applications of Centrifugal Disc Finishing Machine

- 5 Advantages of Centrifugal Disc Finishing Machine

- 6 Media Selection

- 7 Why Choose Rax Machine for Your Centrifugal Disc Finishing Machine?

Function of the Centrifugal Disc Finishing Machine

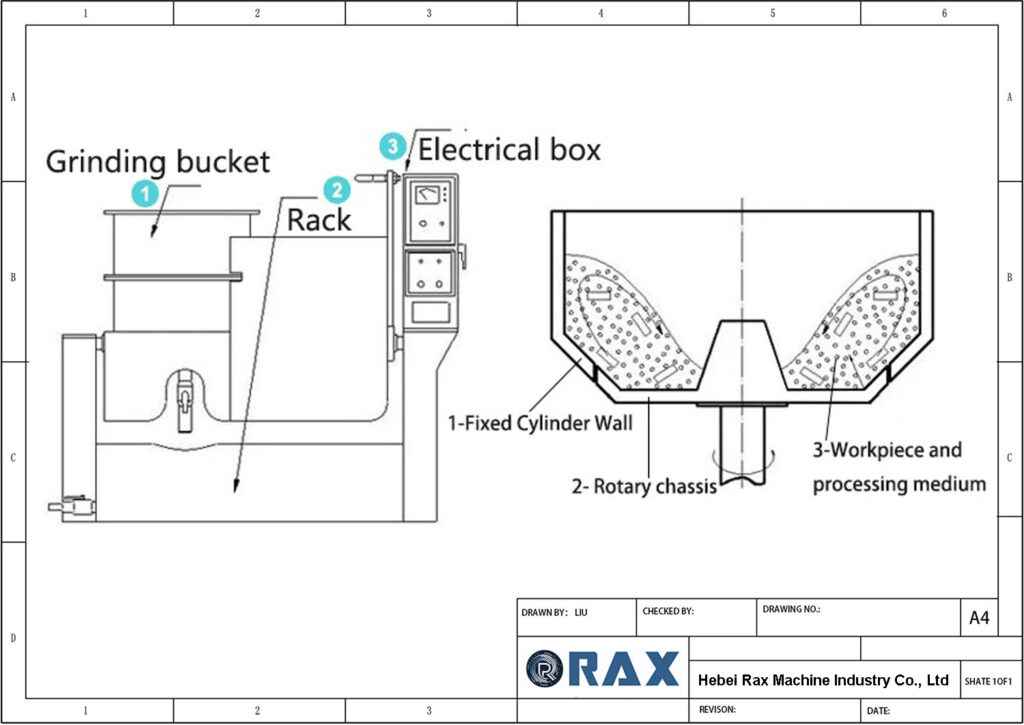

The Centrifugal Disc Finishing Machine uses the centrifugal force to create a high-energy environment needed for mass finishing processes. For the machine to work as required, it needs to follow a simple process. The good news is that the functioning doesn’t require too much interaction, hence reduced labor.

Parts and finishing media are loaded into the bowl. A spinning disc then propels it upwards. Once they reach the top of the bowl, the media and the parts fall against the stationary walls. This creates a scrubbing and finishing action. The cycle continues, which results in deburring, polishing, and refining surface edges.

How the Centrifugal Disc Finishing Machine Works

- Loading: The first action involves loading the materials into the bowl.

- Setting up the machine: Setting up the machine will just require establishing that all the known parameters are in the correct settings. Find out the disc speed, cycle time, and other similar parameters according to the media used and what effect is desired.

- The centrifugal action: The next step is to start the finishing process using the centrifugal force. The disc will start spinning which will result in moving the parts and the media upwards. During this process, the media and parts will constantly rub against each other.

- Deburing and polishing: The media operate like abrasive surfaces that remove defects, burrs, and sharp edges as the parts rub against each other. During this specific stage, the product surface finish may be refined and refurbished to achieve better surface quality and feel.

- Unloading, separation, and cleaning: The last part is the unloading, which is done once the machine stops spinning. You can then separate the finished parts from the media. You can also clean and dry them depending on the materials and media used.

Key Features of the Centrifugal Disc Finishing Machine

- The cylindrical bowl houses the finishing media and parts

- A rotating disc that spins to create a centrifugal force

- Finishing media, which can be ceramic, plastic, or organic

- Compounds for cutting or polishing

- Dosing System (Optional)

- The control panel provides a user interface for operating the machine

- Safety features like a secure lid with interlocks, emergency stop buttons, and proper ventilation

- Discharge System (Optional)

The Applications of Centrifugal Disc Finishing Machine

- Aerospace: Unlike other methods, Centrifugal disc finishing performs perfectly in eliminating burrs and producing a good surface finish suitable for parts such as turbine blades, gears, and landing gear components.

- Automotive: The geometry and dimension tolerance of valves, pistons, and other parts of the engine are done more precisely using the Centrifugal Disc machine.

- Medical: Precise finishing is crucial for medical devices like implants and surgical instruments.

- Electronics: The machine’s ability to precisely finish small, delicate parts makes it ideal for the electronics industry.

- Jewelry: Centrifugal disc finishing, together with the right media selection, can be used to polish gold, silver, platinum, and other precious metals to a shiny finish.

Advantages of Centrifugal Disc Finishing Machine

1. Faster Cycle Times

This machine saves you time of polishing your workpiece as it works 10 to 30 times faster than conventional vibratory tumblers. In other words, it will mean a substantial increase in production output and a reduction in labor costs. The shorter processing times, consequently, result in lower energy use, hence making the whole process even more cost-effective.

2. Uniform Finishing

The nearly uniform centrifugal force helps to properly clean all parts even in difficult-to-clean areas and complex shapes. It prevents patchiness or holes that may develop during the operation process with vibration methods. You will surely have the ideal finish with just one run of the machine.

3. Improved Quality

The media and parts are subjected to a centrifugal force, which results in a smoother and more precise output. This is important for components requiring a high-quality surface finish for functionality or appearance.

The deburring capabilities of Centrifugal disc finishing are very effective in removing any sharp edges or defects that a machining process can leave behind.

4. Versatility

This machine can be used for a variety of sizes, shapes, and workpiece materials. It can deal with fragile parts without bringing any damage. Versatility is its greatest strength, which makes it suitable for finishing in different sectors such as aerospace, automotive, electronics, medical devices, and general metalworking.

Not to mention the fact that the machine’s versatility lets you finish a broader spectrum of parts on a single machine, it lowers the need for expensive equipment, which can be costly.

5. Easy to Use

The centrifugal disc finishing machine offers an operation that is clear, easy, and straightforward. It will enable you to set values like speed, time, and compound type. This means that the championing process can be refined to get the exact finishing result needed for each particular application. The user-friendly design of the algorithm minimizes the required training time and yields consistent results across operators.

Media Selection

The optimum media for your centrifugal disc finishing machine could range from different polishing materials based on the exact requirement and the required surface finish. Some of the common media types include:

- Ceramic Media: Ceramic grains are the common media ones having diameters from minute to coarse with different shapes and sizes. The structures would be in shapes such as triangles, pyramids, and stars amongst others. You have the flexibility of using different shapes to get the desired aggressiveness.

- Plastic Media: Plastic can polish and refine delicate parts because it’s less aggressive compared to ceramic. They also come in different shapes and sizes to give the desired results.

- Organic Media: Organic media include, for instance, walnut shells or corn cobs. They’re the most gentle option of media used for pre-cleaning, burnishing, and matte finishing. These are frequently used in the molding of plastics and valuable metals.

Why Choose Rax Machine for Your Centrifugal Disc Finishing Machine?

At Rax Machine, we know that quality, efficiency, and affordability are the pillars of any scalable and profitable business. Our Centrifugal Disc Finishing Machines are crafted out of high-quality materials and sophisticated design for superior performance and enduring operation. We guarantee the best customer service and technical support so that you can maximize your return on this investment.

Furthermore, we offer affordable factory-direct pricing whereby you would spend less and still achieve excellent final finishes. Make Rax your choice and witness the power of a finishing solution company focused on your needs.