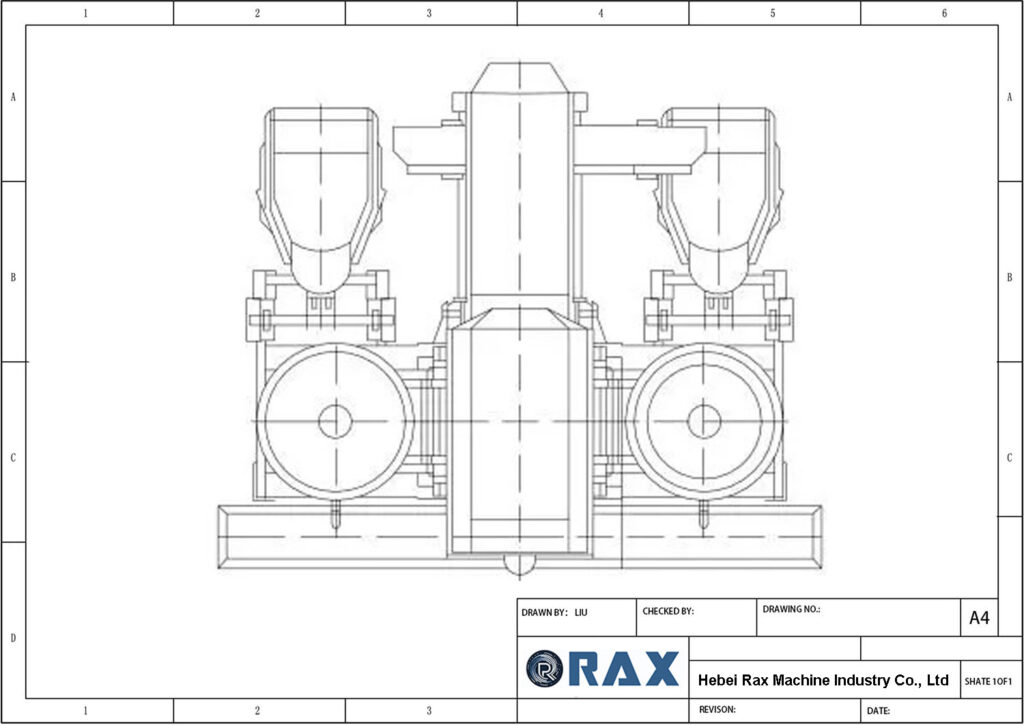

Automatic Centrifugal Disc Finishing Machine

As the name suggests, an automatic centrifugal disc finishing machine is an automatic mass finishing machine used for parts batch polishing, deburring, edge rounding and surface finishing. It is also called Automatic Turbo Centrifugal Disk Finisher. It minimizes the processing time or cycles of the vibratory deburring tumbler by 30X, leading to reduced operational costs. Compared to other vibratory polishing and finishing machines as well as rumbling deburring machines, it offers better automated tumble finishing.

Built to be easily integrated into a complete automated or semi-automated system, the automatic centrifugal disc finishing machine features a built-in media separator to facilitate continuous operation. The key benefits include automatic control and relatively short processing time. The machine can be used in various applications such as finishing stampings, casting and machined parts. Other application includes rubber deflashing, cleaning special plastic and synthetic material, processing watchmaking parts as well as jewellery finishing.