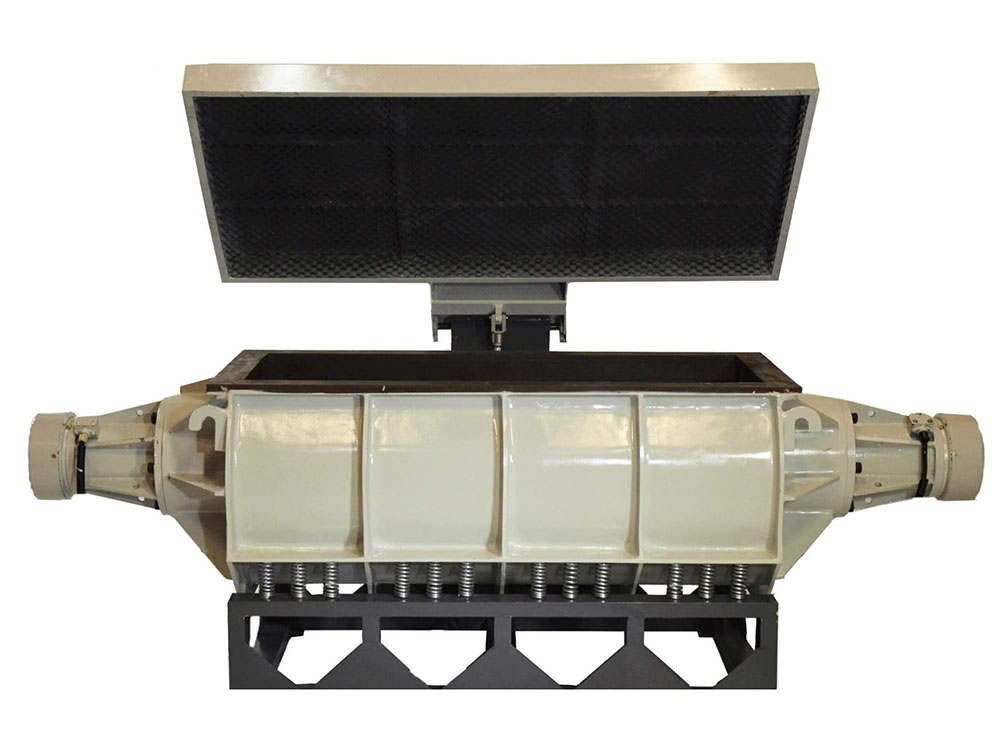

Soundproof Cover

The soundproof cover protects operators from loud noise by effectively decreasing structure-borne and airborne noise. It also plays a critical role of minimising chemical splash. Typically, the effective ones are full sound-absorbing cabins and the design of both enclosing components of each soundproof cover does not interfere with the vibratory finishing machine’s functionality.

Made using special technology, the soundproof cover helps minimise the noise level by 57% compared to a machine operating with a soundproof cover. However, the level of noise relies on various factors, including the machine size, type and size of media and components utilised in the process. The drive system also generates the vibratory force that affects the noise level. The cover ensures that the machines operate quietly, eliminating the need for a special noise deadening enclosure.