Manufacturing professionals face a critical dilemma when selecting surface finishing methods: should they invest in automated mass finishing systems or rely on traditional hand polishing techniques? This decision impacts not only production costs but also final product quality, making it a pivotal choice that directly affects both operational efficiency and customer satisfaction.

Mass finishing offers compelling advantages for high-volume production environments, processing entire batches simultaneously with remarkable consistency. The automated approach dramatically reduces labor requirements while ensuring uniform results across hundreds or thousands of parts. Traditional hand polishing, ωστόσο, remains the gold standard for complex geometries and premium finishes where skilled craftspeople can achieve nuanced results that machines simply cannot replicate.

For manufacturers weighing these options, understanding the technical limitations and appropriate applications of each method is essential to making cost-effective decisions. Με πάνω 20 years of experience providing surface finishing solutions, Rax Machine has observed that many companies achieve optimal results by implementing strategic combinations of both techniques—using mass finishing for initial processing while reserving hand polishing for critical surfaces where precision matters most.

Πίνακας περιεχομένων

What Makes Mass Finishing the Industry Standard for High-Volume Production?

“Mass finishing provides manufacturers with uniform surface treatment results at scale while significantly reducing labor costs compared to traditional manual finishing methods.”

The Science Behind Automated Surface Treatment

Automated surface finishing leverages fundamental physical principles to achieve consistent results. Most mass finishing systems utilize media, ενώσεις, and mechanical energy to create controlled abrasion against workpiece surfaces. This scientific approach enables manufacturers to precisely control factors including cutting action, lubricating effects, και δυνατότητες καθαρισμού.

The process works through a combination of friction, σύγκρουση, and chemical interaction between the media and parts. These forces uniformly remove burrs, στρογγυλές άκρες, and improve surface roughness across all exposed part surfaces. Unlike manual operations that fatigue over time, mechanical systems maintain consistent energy application throughout production runs.

How Does Mass Finishing Achieve Uniform Results?

Mass finishing techniques achieve remarkable uniformity through carefully controlled process parameters. In vibratory finishing, for example, the amplitude and frequency of vibration are precisely calibrated to produce specific finish characteristics. Parts move freely through a mass of media that contacts all accessible surfaces simultaneously.

Αυτό “set-it-and-forget-it” capability represents a significant advancement over traditional hand polishing, where results depend heavily on operator technique, pressure variations, and attention to detail. With mass finishing, once process parameters are established, they remain consistent across production batches—something impossible to achieve through manual methods.

Comparison of Industrial Surface Treatment Methods

| Μέτρηση απόδοσης | Χειροκίνητο φινίρισμα | Δονητικό φινίρισμα | Tumble Finishing | Φυγόκεντρος φινίρισμα | High-Energy Finishing |

|---|---|---|---|---|---|

| Χρόνος επεξεργασίας (hrs/100 parts) | 25-40 | 3-6 | 4-8 | 1-3 | 0.5-1 |

| Ώρες εργασίας (ανά 1000 εξαρτήματα) | 250-400 | 5-10 | 6-12 | 4-8 | 3-5 |

| Surface Roughness Consistency (Ra%) | ±30% | ± 10% | ± 12% | ± 8% | ± 5% |

| Ποσοστό απομάκρυνσης υλικού (μm/min) | 2-5 | 0.5-2 | 0.8-2.5 | 3-8 | 10-20 |

| Κατανάλωση ενέργειας (kWh/100 parts) | 5-8 | 15-25 | 12-20 | 30-50 | 40-65 |

When Production Volume Demands Automation

The transition point from traditional to mass finishing often occurs when production volumes reach a threshold where manual finishing becomes economically unsustainable. Manufacturers typically begin considering manufacturing surface finishing automation when batch sizes exceed several hundred identical parts or when production rates demand processing thousands of components weekly.

At these volumes, the limitations of manual methods become painfully evident. Labor costs escalate, quality consistency suffers, and production bottlenecks form. Mass finishing systems eliminate these constraints by processing hundreds or thousands of parts simultaneously with minimal operator intervention.

Labor Cost Reduction: The Numbers Behind the Savings

The economic argument for mass finishing becomes clear when examining labor requirements. Where traditional hand finishing might require 25-40 hours of skilled labor to process 100 εξαρτήματα, a properly configured vibratory system can process the same quantity in just 3-6 hours with only minimal oversight. This represents an approximate 80-90% reduction in labor hours.

These labor savings translate directly to decreased production costs. While mass finishing equipment requires initial capital investment, the return on investment typically materializes within 6-18 μήνες για εργασίες μεγάλου όγκου. The reduction in skilled labor dependency also helps manufacturers address workforce challenges in regions facing skilled labor shortages.

Key Limitations in Complex Geometries

Despite its advantages, mass finishing vs traditional methods reveals certain limitations. Complex parts with internal features, deep recesses, or extremely fragile geometries may not achieve optimal results through mass finishing alone. These areas may remain inaccessible to media or receive inconsistent treatment compared to external surfaces.

Επιπλέον, mass finishing cannot fully replicate the nuanced control of hand polishing for certain high-value applications where aesthetic perfection is required. Fine jewelry, custom firearms, and certain medical instruments may still benefit from skilled hand finishing or hybrid approaches combining mass and manual techniques.

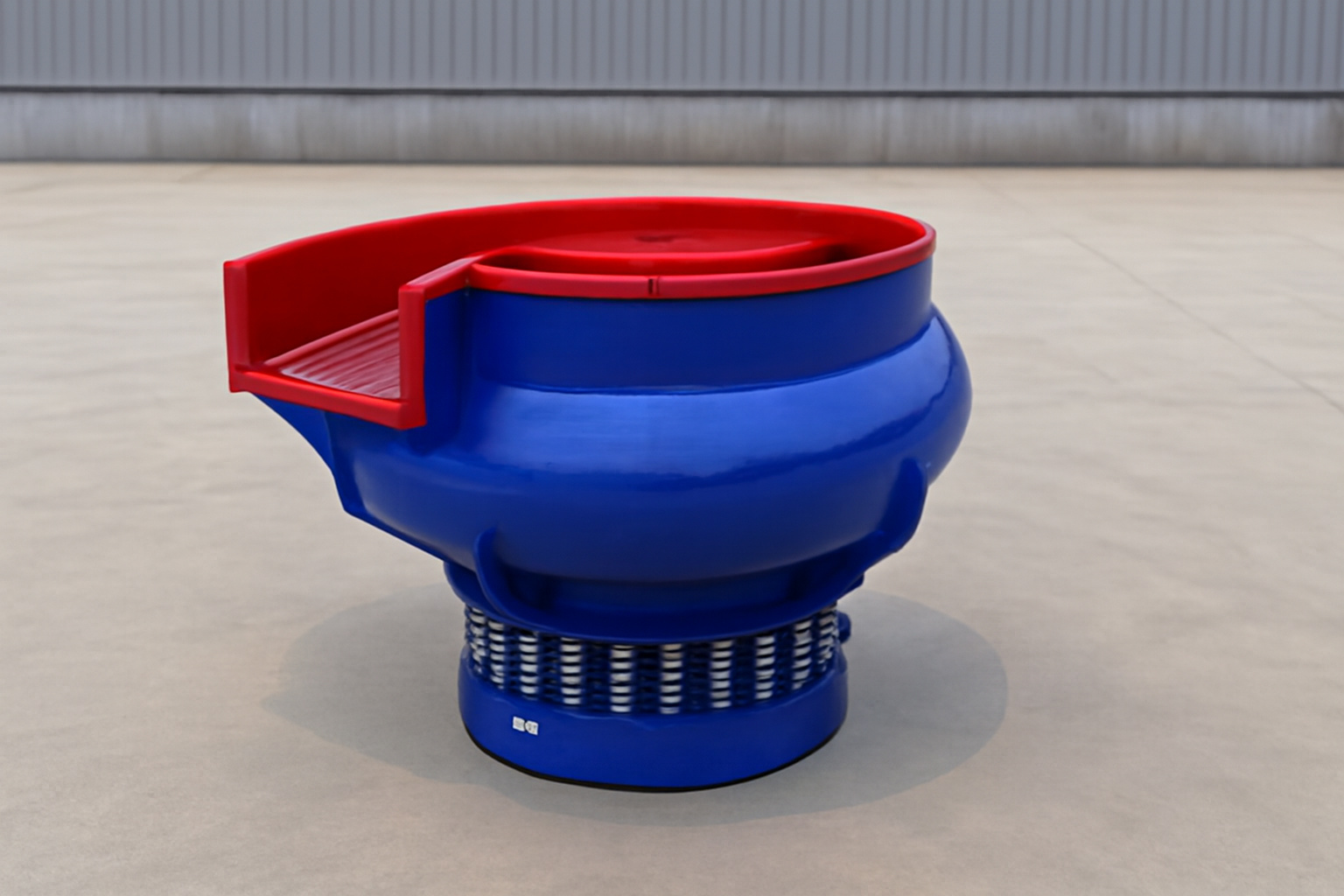

[Επιλεγμένη εικόνα]: Industrial centrifugal mass finishing machine processing aluminum components in a high-volume manufacturing facility [Αλλοτριώ: High-efficiency centrifugal mass finishing equipment for industrial surface treatment]

When Does Hand Polishing Justify Its Premium Cost?

“Hand polishing delivers superior surface quality through precise pressure control and adaptive technique that automated finishing systems cannot replicate for certain high-value applications.”

The Artisan’s Touch: Achieving Premium Surface Quality

Traditional polishing methods excel in applications requiring exceptional surface luster and finish uniformity. Skilled artisans develop an intuitive understanding of how materials respond to different compounds and techniques. This sensory feedback loop—feeling the resistance change as surface quality improves—enables real-time adaptations impossible in automated systems.

Manual metal polishing techniques create distinctive finishes with character and depth, particularly evident in premium products where surface appearance directly influences perceived value. A hand-polished watch case or luxury pen barrel exhibits a dimensional luster that machine finishes rarely achieve, with subtle variations that catch light in ways mass-finished surfaces cannot match.

Critical Applications in Luxury and Aerospace Industries

Industries where perfection justifies premium costs predominantly utilize hand polishing. Luxury watch manufacturers continue traditional artisanal metal finishing for visible components despite the higher expense. Ομοίως, aerospace manufacturers employ manual techniques for critical components where surface irregularities could compromise performance or safety.

Medical implant manufacturers rely on skilled craftsmanship for components that will remain in the human body for decades. The strategic combination of automated pre-processing with final hand polishing creates optimal results for these high-stakes applications where tolerances are measured in microns.

Σύγκριση μετρήσεων ποιότητας: Hand vs. Automated Polishing

| Παράμετρος ποιότητας | Hand Polishing | Δονητικό φινίρισμα | Φυγόκεντρος φινίρισμα | Σύρσιμο | Βιομηχανικό σημείο αναφοράς |

|---|---|---|---|---|---|

| Τραχύτητα (RA μm) | 0.01-0.05 | 0.1-0.3 | 0.05-0.2 | 0.03-0.15 | < 0.2 |

| Edge Definition Control | Εξοχος | Φτωχός | Fair | Καλός | Application-dependent |

| Selective Area Processing | Ακριβής | Not possible | Not possible | Περιωρισμένος | Often required |

| Ανακλαστικότητα επιφάνειας (%) | 95-99 | 70-85 | 80-90 | 85-95 | > 90 for premium |

| Processing Cost ($/in²) | 3.50-15.00 | 0.20-0.80 | 0.40-1.20 | 0.75-2.50 | Varies by industry |

Complex Geometries That Challenge Automation

Components with intricate features, deep recesses, or variable surface requirements frequently necessitate manual processing. While mass finishing excels with simple geometries, complex parts with internal channels or tight corners remain challenging for tumbling media to access consistently. Hand polishers can navigate these areas with specialized tools and adaptive techniques.

Products combining multiple materials or requiring selective finishing also benefit from manual approaches. ΕΝΑ “touch-up artist” can precisely address specific areas without affecting adjacent surfaces—a level of control automated systems simply cannot match, regardless of technological advancement.

Is Hand Polishing Worth the Investment?

The economic justification for traditional polishing methods depends largely on production volume, part value, και απαιτήσεις ποιότητας. For high-value components where surface quality directly impacts functionality or market position, the premium cost becomes inconsequential compared to the value added.

The calculation changes dramatically for commodity products or components where functional tolerances permit wider variation. When evaluating mass finishing vs traditional hand polishing economically, manufacturers should consider not just per-part labor costs, but also rejection rates, rework expenses, and the potential market premium for superior finishes.

Training Requirements for Skilled Polishers

Developing competent manual polishers requires substantial investment in training and mentorship. Skilled practitioners typically need 1-3 years of guided practice to achieve mastery of traditional polishing methods. This apprenticeship model creates unique human capital that remains valuable despite automation advances.

The high-precision finishing skills developed through this training transfer across industries and materials, making skilled polishers valuable assets in manufacturing environments. Companies that maintain hand polishing capabilities often develop proprietary techniques that become competitive advantages in specialty markets where mass finishing cannot meet quality requirements.

How Do Surface Quality and Consistency Compare Between Methods?

When evaluating mass finishing vs traditional hand methods, the differences in surface quality and uniformity become immediately apparent through both objective measurements and subjective assessment. Manufacturing engineers must balance these quality considerations alongside production requirements. While automated processes excel in consistency and throughput, traditional techniques can achieve superior finishes in specific applications where aesthetic considerations or functional requirements demand exceptional surface characteristics.

“Surface quality measurements reveal distinct performance profiles between mass finishing and traditional hand polishing, with each method offering specific advantages depending on application requirements and material properties.”

Measuring Surface Roughness: Ra Values Compared

Surface roughness, measured as Ra (αριθμητική μέση τραχύτητα) in micrometers or microinches, provides the most objective comparison between metalworking finishing processes. Hand polishing can achieve Ra values as low as 0.01-0.05μm on optimal materials when performed by skilled technicians. Σε αντίθεση, standard vibratory mass finishing typically produces Ra values between 0.2-0.8μm, though specialized high-energy processes can approach 0.1μm.

This quantitative difference reflects the fundamental mechanics of each approach. Hand polishing allows progressive refinement through increasingly finer abrasives applied with precisely controlled pressure. Mass finishing relies on random media impacts that efficiently reduce major irregularities but struggle to achieve the absolute smoothness possible through directed manual techniques.

Consistency Across Batches: The Data Speaks

While hand polishing can achieve superior absolute finishes, mass finishing demonstrates remarkable consistency advantages. Production data reveals that vibratory and centrifugal systems produce surface roughness variations of only ±8-15% across large batches. Manual polishing, even by skilled operators, typically shows variations of ±25-40% when measured across equivalent part quantities.

This consistency advantage becomes particularly significant in regulatory environments requiring validated processes. Medical device and aerospace manufacturers often select mass finishing for this reason, as the documented repeatability simplifies compliance with stringent quality systems. The microfinish predictability enables more reliable engineering specifications.

Surface Quality Comparison by Finishing Method

| Παράμετρος ποιότητας | Hand Polishing | Δονητικό φινίρισμα | Φυγόκεντρος φινίρισμα | Σύρσιμο | Βιομηχανικό πρότυπο |

|---|---|---|---|---|---|

| Best Achievable Ra (μm) | 0.01-0.05 | 0.2-0.8 | 0.08-0.3 | 0.05-0.2 | Application-dependent |

| Batch-to-Batch Consistency (RA %) | ±25-40% | ±10-15% | ±8-12% | ±10-18% | ±15% typical requirement |

| Edge Retention Factor | 0.9-0.95 | 0.6-0.75 | 0.65-0.8 | 0.75-0.85 | 0.8 minimum for precision |

| Maximum Material Removal Rate (μm/ώρα) | 5-20 | 2-8 | 10-25 | 5-15 | Application-dependent |

| Surface Texture Uniformity Score (1-10) | 7-9 | 8-9 | 7-8 | 8-9 | 7+ acceptable |

Visual Differences That Customers Notice

Surface texture characteristics extend beyond quantitative measurements to include qualitative aspects that customers readily perceive. Hand-polished components typically exhibit directional patterns that create distinctive light reflection properties. These controlled directional finishes can enhance aesthetic appeal in consumer products where visual differentiation adds value.

Mass finished parts display non-directional, “butter-smooth” surfaces without visible tool marks. This uniform appearance benefits products where consistency across multiple visible surfaces is essential. The absence of directional patterns also improves certain functional characteristics, such as reduced friction in moving assemblies and enhanced corrosion resistance due to the absence of microscopic channels.

Material-Specific Finishing Results

Material properties significantly influence finishing outcomes across different methods. Softer materials like aluminum, ορείχαλκος, and copper respond differently to mass finishing than to hand techniques. Mass finishing tends to produce more uniform results on these materials but may struggle with selective material removal needed for complex parts with varying hardness zones.

Harder alloys like stainless steel and titanium present unique challenges for surface quality comparison. These materials often benefit from the intensive energy application possible in high-energy mass finishing, which can overcome their inherent resistance to abrasion. Ωστόσο, the skilled application of specialized compounds in hand polishing can achieve mirror finishes on these materials that mass processes struggle to replicate.

Durability of Different Surface Treatments

Surface finish durability varies significantly between processing methods. Mass finished surfaces typically demonstrate superior corrosion resistance due to the compressive stress layer created through media impact. This work hardening effect can increase surface hardness by 10-30% compared to pre-processed conditions, extending component lifespan.

Hand polishing creates less residual compressive stress but can achieve superior aesthetics for applications where appearance outweighs durability concerns. Για βέλτιστη απόδοση, many manufacturers employ hybrid approaches—using mass finishing for base preparation and selective hand polishing for critical visual areas—combining the strengths of both metalworking finishing processes.

[Επιλεγμένη εικόνα]: Comparison of surface profiles showing microscopic differences between mass-finished and hand-polished stainless steel samples under identical lighting conditions [Αλλοτριώ: Side-by-side comparison of mass finished versus hand polished surface quality under magnification]

What’s the Optimal Hybrid Approach for Your Manufacturing Needs?

The debate between mass finishing vs traditional hand polishing often presents these methods as competing alternatives, but forward-thinking manufacturers are increasingly adopting hybrid approaches that leverage the strengths of both techniques. By strategically integrating automated and manual processes, companies can optimize both quality and efficiency. This balanced methodology allows manufacturers to direct resources precisely where they deliver maximum value, applying mass finishing for broad surface preparation while reserving skilled hand work for areas where superior finish quality justifies the additional investment.

“A well-designed hybrid finishing strategy combines the efficiency and consistency of mass finishing with the precision and quality of traditional hand polishing to optimize both production costs and surface quality outcomes.”

Identifying Critical vs. Non-Critical Surfaces

The foundation of any effective hybrid approach begins with a systematic classification of component surfaces. Critical surfaces—those visible to customers, subject to precision mating with other components, or essential to product functionality—often justify higher finishing investments. Αντίθετα, non-critical surfaces with purely functional requirements can typically achieve adequate performance through more economical mass finishing methods.

This classification process should be formalized through product engineering documentation, clearly identifying surfaces requiring hand finishing versus those suitable for automated methods. Many manufacturers implement a simple three-tier system: Class A surfaces (premium finish required), Class B surfaces (standard production finish acceptable), and Class C surfaces (functional finish only), with specific finishing processes mapped to each classification.

The Two-Stage Finishing Process

The most efficient hybrid surface finishing implementation typically follows a two-stage approach. Πρώτα, components undergo mass finishing to establish baseline surface characteristics—removing manufacturing marks, establishing uniform texture, and achieving consistent dimensional characteristics across all surfaces. This creates a standardized foundation for subsequent operations.

In the second stage, selective hand finishing targets only those surfaces classified as critical. Αυτό “best of both worlds” methodology dramatically reduces manual labor requirements while still delivering premium finishes where they matter most. The standardized base condition from the first stage also makes the subsequent hand work more predictable and efficient, as technicians work from a consistent starting point.

Cost-Benefit Analysis of Hybrid Manufacturing Surface Finishing

| Process Approach | Initial Equipment Investment ($) | Labor Cost per 1000 Μέρη ($) | Χρόνος Διαδικασίας (hrs/1000 parts) | Ποιότητα συνέπειας (1-10) | Ετήσιο κόστος συντήρησης ($) |

|---|---|---|---|---|---|

| 100% Hand Finishing | 5,000-15,000 | 8,500-12,000 | 250-400 | 5-7 | 1,000-2,500 |

| Basic Hybrid (80/20 Split) | 45,000-85,000 | 2,800-4,200 | 70-120 | 7-8 | 3,500-7,000 |

| Advanced Hybrid (90/10 Split) | 75,000-150,000 | 1,500-2,800 | 40-80 | 8-9 | 5,000-10,000 |

| 100% Μαζικό Φινίρισμα | 120,000-250,000 | 800-1,500 | 25-60 | 8-9 | 8,000-15,000 |

| Fully Automated Production Line | 350,000-1,200,000 | 400-800 | 15-30 | 9-10 | 15,000-40,000 |

ROI Calculation: When to Invest in Each Method

The financial justification for hybrid finishing techniques depends heavily on production volume, πολυπλοκότητα των μερών, και απαιτήσεις ποιότητας. For monthly volumes under 500 μονάδες, the capital investment in mass finishing equipment rarely delivers adequate return unless the parts are exceptionally labor-intensive to finish manually. At moderate volumes (500-5,000 monthly), basic mass finishing equipment supplemented by targeted hand polishing often provides the optimal cost-quality balance.

When calculating ROI, manufacturers should consider not only direct labor savings but also rejection rate reduction, throughput improvements, and quality consistency benefits. A comprehensive ROI analysis should include these factors, typically showing that hybrid approaches reach breakeven fastest for mid-volume producers with mixed quality requirements.

Equipment Selection for Different Production Scales

Equipment choices for hybrid systems should align with production volume and part characteristics. For small-batch manufacturers (under 1,000 monthly units), compact vibratory systems combined with dedicated finishing stations offer cost-effective solutions. Mid-volume producers benefit from higher-capacity tub vibrators or small centrifugal systems paired with semi-automated hand finishing tools.

High-volume manufacturers should consider continuous-flow vibratory systems or multi-stage processing lines that integrate mass finishing with targeted robotic or manual stations for critical surfaces. The capital investment increases substantially, but per-part processing costs decline dramatically, making these systems economical only above certain volume thresholds, τυπικά 10,000+ monthly units.

Case Studies: Successful Hybrid Implementation

A medical device manufacturer successfully implemented a hybrid approach for titanium implant components. By using high-energy centrifugal finishing for primary surface preparation followed by selective hand polishing of critical interface surfaces, they reduced overall finishing time by 65% while improving surface consistency and reducing rejection rates from 5.2% να 1.8%.

Ομοίως, a luxury consumer products company adopted a two-stage process for stainless steel accessories. Mass vibratory finishing established base surface conditions, followed by targeted hand buffing of visible surfaces. This approach reduced labor costs by 70% compared to their previous all-manual process while maintaining the premium surface quality that distinguished their brand in the marketplace.

Σύναψη

In the ongoing discussion of mass finishing versus traditional hand polishing, it’s clear that each method has its unique strengths tailored to different manufacturing needs. Companies must evaluate their production volumes, part geometries, and quality requirements to determine the best approach.

As manufacturers face increasing demands for efficiency and quality, strategic integration of both mass finishing and hand polishing presents a viable path forward. This hybrid methodology combines the best of both worlds, enhancing productivity while maintaining high standards for critical applications.

For businesses ready to explore these finishing solutions, finding a partner who understands these challenges is key. Στο Μηχανή Rax, our expertise in mass finishing equipment can help you navigate your specific needs and achieve optimal surface finishing results.

Συχνές Ερωτήσεις

-

Q: What is mass finishing and how does it differ from traditional hand polishing?

ΕΝΑ: Mass finishing is an automated process that uses abrasive media to improve the surface of multiple workpieces simultaneously, making it ideal for high-volume production. Σε αντίθεση, traditional hand polishing is a manual technique used for intricate or high-value components, yielding higher precision and an artisanal finish.

-

Q: What are the advantages of using mass finishing over hand polishing?

ΕΝΑ: Mass finishing offers several advantages, including significantly increased efficiency, cost reduction in labor, and consistent surface quality across batches. It is particularly beneficial for parts that require uniform treatment in large quantities, while hand polishing is more suited for detailed work requiring high precision.

-

Q: In what scenarios is hand polishing preferred over mass finishing?

ΕΝΑ: Hand polishing is preferred in applications where exceptional precision and attention to detail are necessary, such as luxury goods, εξαρτήματα αεροδιαστημικής, or complex geometries. It allows skilled artisans to achieve superior surface finishes that may not be possible with mass finishing.

-

Q: What types of mass finishing techniques are commonly used in manufacturing?

ΕΝΑ: Common mass finishing techniques include vibratory finishing, φινίρισμα αναρρόφησης, barrel finishing, and centrifugal finishing. Each method uses different types of abrasive media and is suited for different applications, depending on the desired surface finish and material.

-

Q: What are the key limitations of mass finishing?

ΕΝΑ: While mass finishing is efficient, it has limitations including challenges with delicate parts, intricate details, and strict tolerances. Some applications may still require hand polishing to achieve the desired level of surface finish.

-

Q: How do manufacturers balance cost and quality between mass finishing and hand polishing?

ΕΝΑ: Manufacturers often adopt a hybrid approach, using mass finishing for initial bulk processing and complementing it with hand polishing for critical areas requiring finer detail. This strategy allows them to optimize production costs while maintaining high-quality finishes where necessary.

-

Q: What materials are best suited for mass finishing?

ΕΝΑ: Mass finishing is suitable for a wide range of materials including metals, πλαστικά είδη, και κεραμική. Ωστόσο, the specific application of each finishing method and media type depends on the material properties and the desired surface characteristics.

-

Q: Can mass finishing methods be used for food-grade applications?

ΕΝΑ: Ναί, mass finishing methods are often used in food-grade applications to produce smooth surfaces that prevent contamination. The processes ensure that all components meet stringent hygiene standards while enhancing their aesthetic appeal.