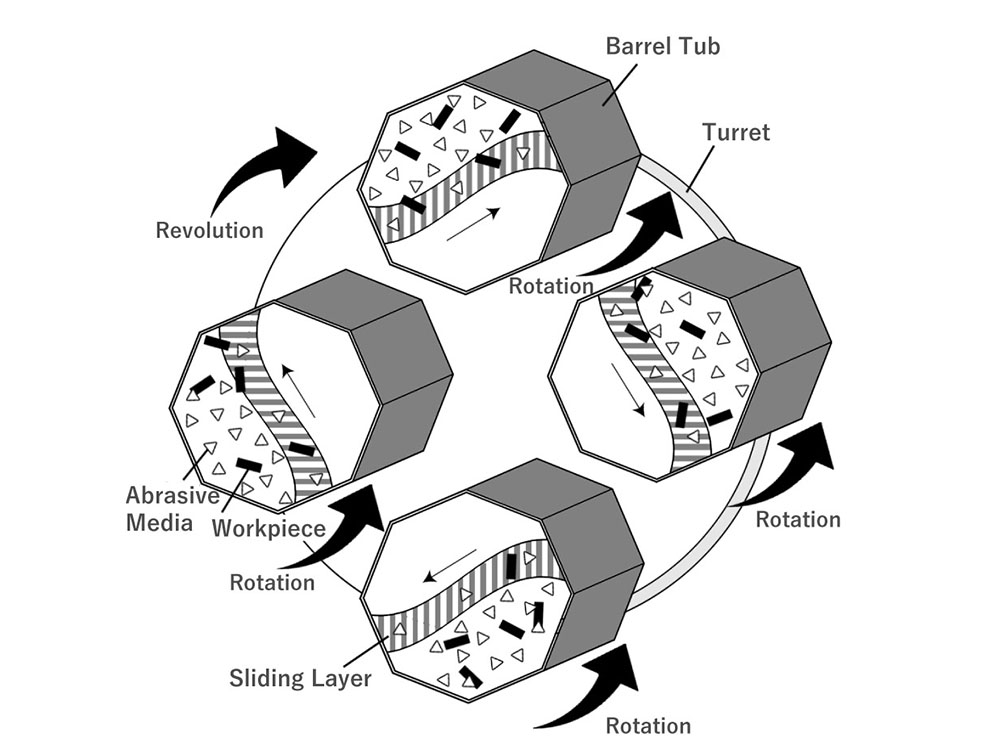

The Harperizer Machine is a vital tool in manufacturing, known for its ability to achieve impeccable surface finishes on various parts and components. Its operation revolves around the principle of centrifugal force: barrels filled with workpieces, abrasive media, and finishing compounds rotate swiftly, inducing vigorous tumbling.

Operating like a Ferris Wheel, each barrel is loaded with a mix of media, parts, water, and compound, and as the turret rotates, it creates a sliding force inside the barrel, causing parts and media to interact in random directions. This machine, also known as a centrifugal barrel finisher or ” Centrifugal Barrel Finishing Machine,” boasts high-speed and precision finishing capabilities. Unlike conventional mass finishing machines, it can exert up to 5 G force for deburring and polishing, giving rapid and flawless surface finishes.

Table of Contents

- 1 How Does a Harperizer Machine Work?

- 2 Key Features of a Harperizer Machine

- 3 Where Did Centrifugal Barrel Tumbling Start?

- 4 Common Applications for Harperizer Machines

- 5 The Benefits of Centrifugal Barrel Finishing

- 6 Types of Materials Processed by Harperizer Machine

- 7 FAQs Related to Harperizer Machine

- 8 Conclusion

How Does a Harperizer Machine Work?

The high speed of the flywheel generates intense centrifugal forces, about 15 to 20 times stronger than gravity. This force causes the contents inside the barrels to slide against each other forcefully, resulting in significant pressure. This pressure allows for quick metal parts processing and ensures consistent, smooth finishes.

Operators can adjust the tumbling speed of the machine, enabling them to achieve different levels of finishing. Lower speeds are ideal for fine polishing, while higher speeds are more suited for aggressive deburring and edge smoothing.

Centrifugal barrel tumbling machines excel at removing substantial burrs and blending lines left by machining. They are also highly effective for polishing and burnishing tasks. By using various types of media, such as ceramic or organic materials like corn-cob, these machines bring different finishes, from super-fine polishing to burr removal.

Key Features of a Harperizer Machine

High-speed processing (up to 400 rpm)

- Optional user-friendly control panel & touch screen

- Consistent & repeatable output

- Ideal for medical, turbine blade, automotive parts, and firearms finishing

- Precise variable speed control

- Durable construction for reliability

- Easy-to-use controls

- Efficient material removal for productivity

- Consistent high-quality finishes

- Versatile for various parts

Where Did Centrifugal Barrel Tumbling Start?

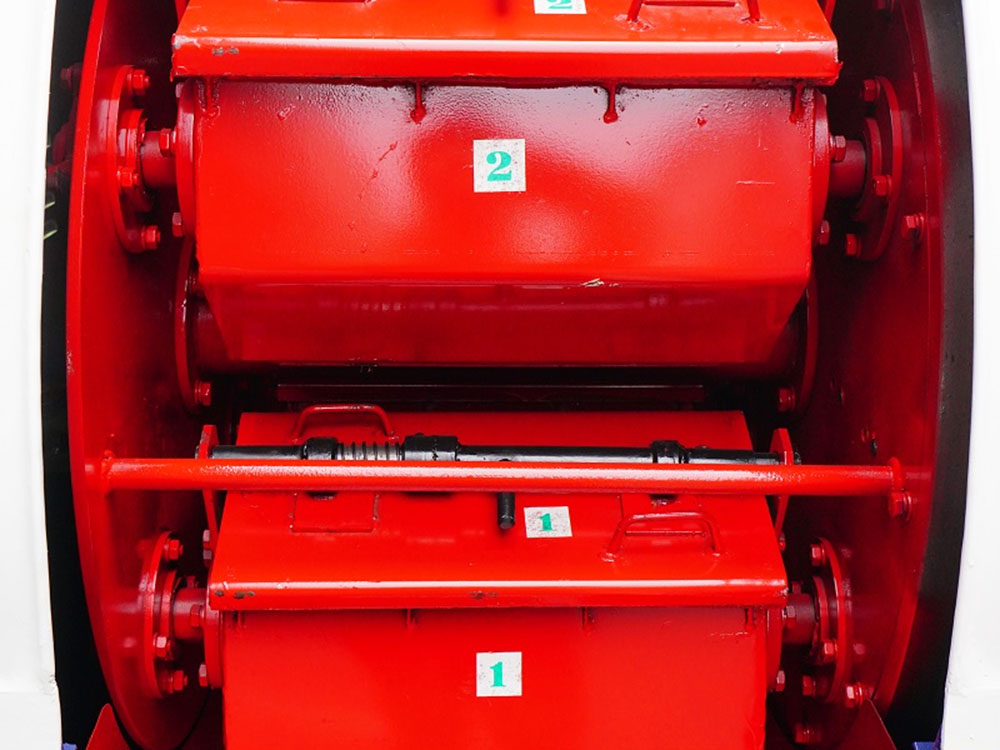

In the 1980s, the technology got the interest of companies worldwide, including those in Korea and Japan. These companies sought to replicate and enhance the technology, focusing on improving the machines’ ergonomics and safety features. This led to the development of mass-finishing machines, which are largely based on Korean design. These machines typically feature four barrels rotating at a one-to-one ratio around a central turret.

Common Applications for Harperizer Machines

Medical Device Industry

Centrifugal barrel finishing is crucial in the medical device sector for achieving precise and smooth surface finishes on implants, surgical instruments, and other medical components. It ensures that these parts meet stringent quality standards and have the required surface integrity for medical use.

Aerospace and Defense

In aerospace and defense industries, precision and reliability are important. This is where centrifugal barrel finishing plays a vital role in refining components such as aircraft parts, missile components, and military hardware. It helps to remove burrs, enhance surface smoothness, and improve component performance and longevity.

Automotive Sector

Harperizer Machines are extensively utilized in the automotive industry for finishing various automotive parts, including engine components, transmission parts, gears, and brackets. These machines contribute to achieving consistent surface finishes, improving part functionality, and enhancing overall product quality.

Along with these industries, Harperizer Machines are also utilized in sectors such as electronics manufacturing, jewelry production, mold and die making, and general manufacturing, where high-quality surface finishes are essential for product performance and aesthetics.

The Benefits of Centrifugal Barrel Finishing

Centrifugal Barrel Finishing offers several key benefits that simplify the finishing process for various industries:

- Reduced Handwork & Manual Labor: With Centrifugal Barrel Finishing, workers can avoid tedious and time-consuming manual deburring and polishing tasks. The machine takes over these processes, freeing up valuable time and reducing labor costs.

- Easy Part Separation: The design of Harperizer Machines allows for effortless separation of parts, preventing damage caused by parts colliding with each other during the finishing process. This makes sure that each part receives individual attention and maintains its integrity.

- No Expensive Tooling Needed: Unlike some other finishing methods, Centrifugal Barrel Finishing does not require expensive tooling or specialized equipment. As long as the part fits within the barrel, it can undergo the finishing process without the need for additional investment.

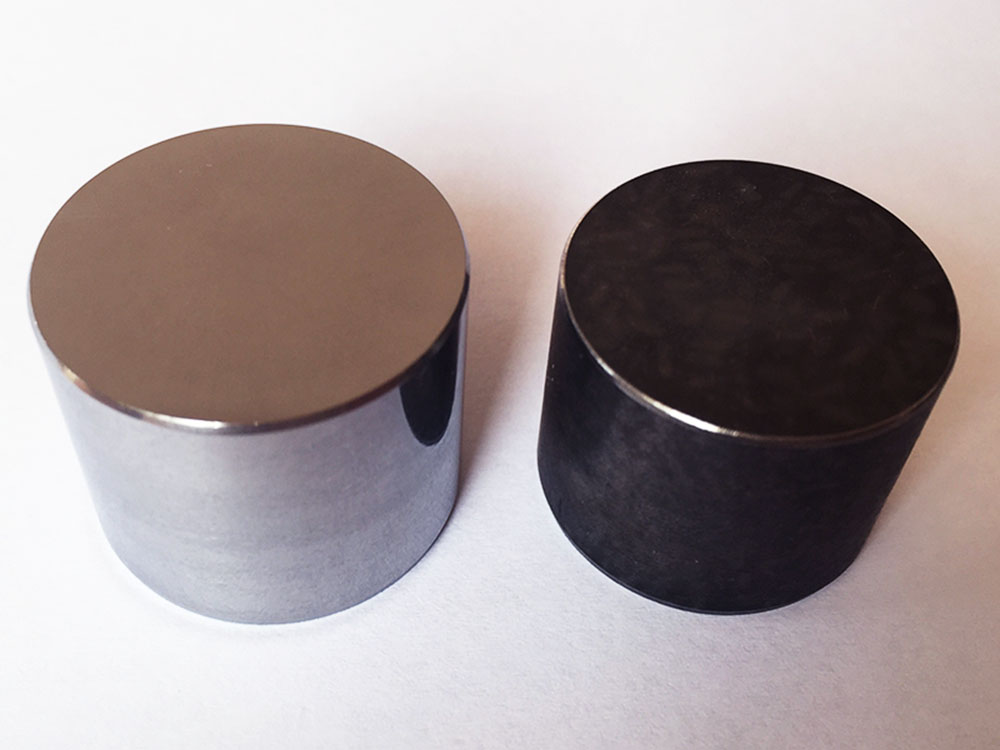

- Achievement of Mirror-Like Finishes: Harperizer Machines are capable of producing flawless, mirror-like finishes on a variety of parts. This level of surface perfection is difficult, if not impossible, to achieve through manual polishing methods.

- Shorter Cycle Times: The efficiency of Centrifugal Barrel Finishing means that parts can be finished in much less amount of time compared to manual methods.

Types of Materials Processed by Harperizer Machine

Here’s a breakdown of the materials commonly processed using this method:

- Plastics: From durable ABS to transparent acrylics, Harperizer Machines offer versatile solutions for processing plastic materials. They can remove imperfections, enhance surface smoothness, and achieve consistent finishes, making them ideal for a wide range of plastic components.

- Ceramics: Harperizer Machines excel at refining ceramic materials such as alumina. Whether it’s smoothing rough edges or achieving precise dimensional accuracy, these machines deliver impeccable finishes that meet the highest quality standards.

- Metals: Harperizer Machines are adept at handling various metals, including steel, stainless steel, aluminum, and titanium. Whether it’s deburring intricate parts or polishing surfaces to a mirror-like finish, these machines ensure exceptional results across all metal types.

- Composites: Harperizer Machines are well-suited for processing composite materials like fiberglass-reinforced plastics (FRP) and carbon fiber-reinforced polymers (CFRP). They effectively remove excess resin, improve surface uniformity, and improve the performance of composite parts.

FAQs Related to Harperizer Machine

How to Use a Harperizer Machine?

Using a Harperizer Machine involves loading the barrels with parts, abrasive media, and finishing compounds. Make sure that the machine is properly set up and balanced. Adjust the settings for speed and time according to the desired finish. Start the machine and monitor the process until completion.

Harperizer Machine vs. Centrifugal Vibratory Tumbling Machine?

Both machines utilize centrifugal force for finishing, but they differ in their operation and application. Harperizer Machines rotate barrels containing parts and media at high speeds, resulting in intense tumbling action. Centrifugal Vibratory Tumbling Machines use a rotating disc or bowl with an eccentric mass to generate vibration, causing parts and media to move in a circular motion.

Conclusion

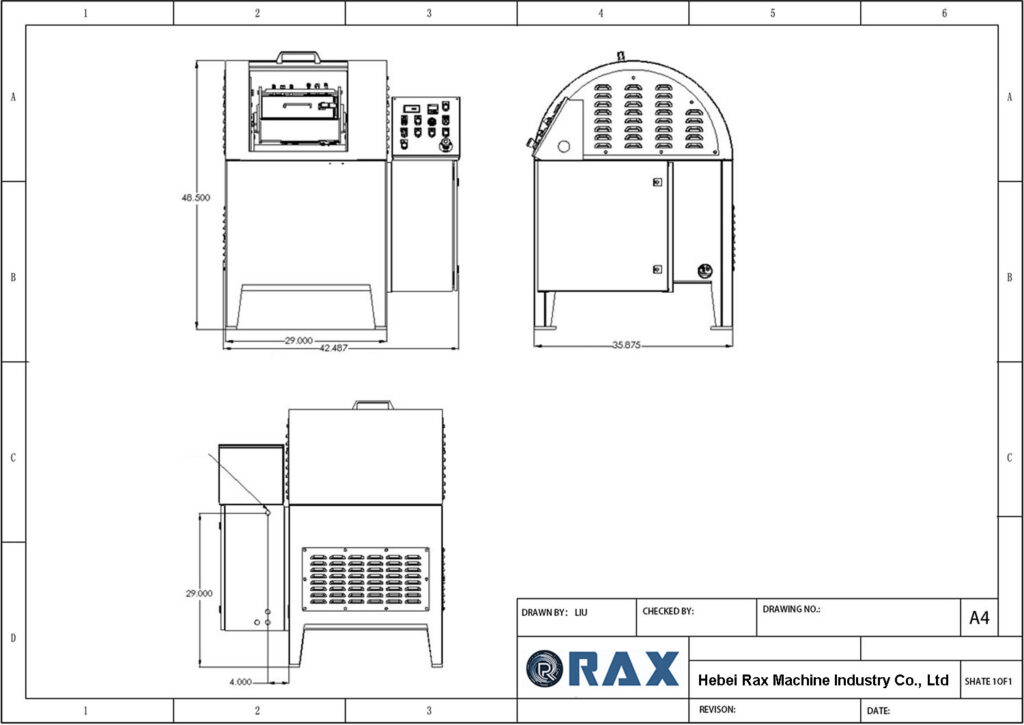

Here at Rax Machine, we’re on a mission to redefine the finishing game with top-notch quality, service that goes above and beyond, and prices that’ll make you smile. From start to finish, we’ve got your back. Choose Rax Machine for a finishing experience that’s anything but ordinary!

High-speed processing (up to 400 rpm)

High-speed processing (up to 400 rpm)