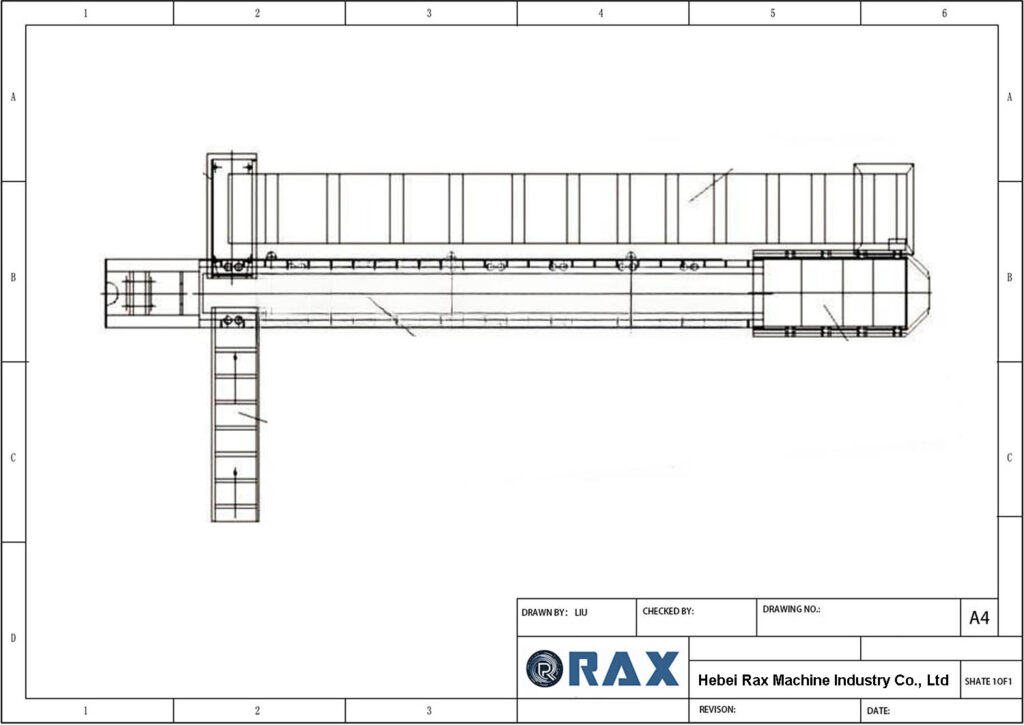

Linear Vibratory Continuous Finishing System

Linear Vibratory Continuous Finishing System, also called Continuous Flow-Thu Longitudinal Vibratory Finishing Machine, is a machine used for mass finishing in surface treatment and finishing of workpieces. It allows continuous parts flow and fully automatic in-line production with programmable control. The machine has a tilt angle and a high-speed converter that enables it to cycle products in less than 10 minutes. This makes it an ideal solution for industries looking for finishing machines that can process large volumes of parts within a short time.

Made from heavy-duty USA DuPont PU material, the linear vibratory continuous finishing system can successfully perform various operations like radiusing, deburring, degreasing, cut-off corner, abrasion and forging in industries that need high capacity. One of the key benefits is that the machine saves on labour costs due to its autonomic nature that requires only one operator to run it. Other benefits include high productivity, gentle separation, intelligent controls as well as easy maintenance.