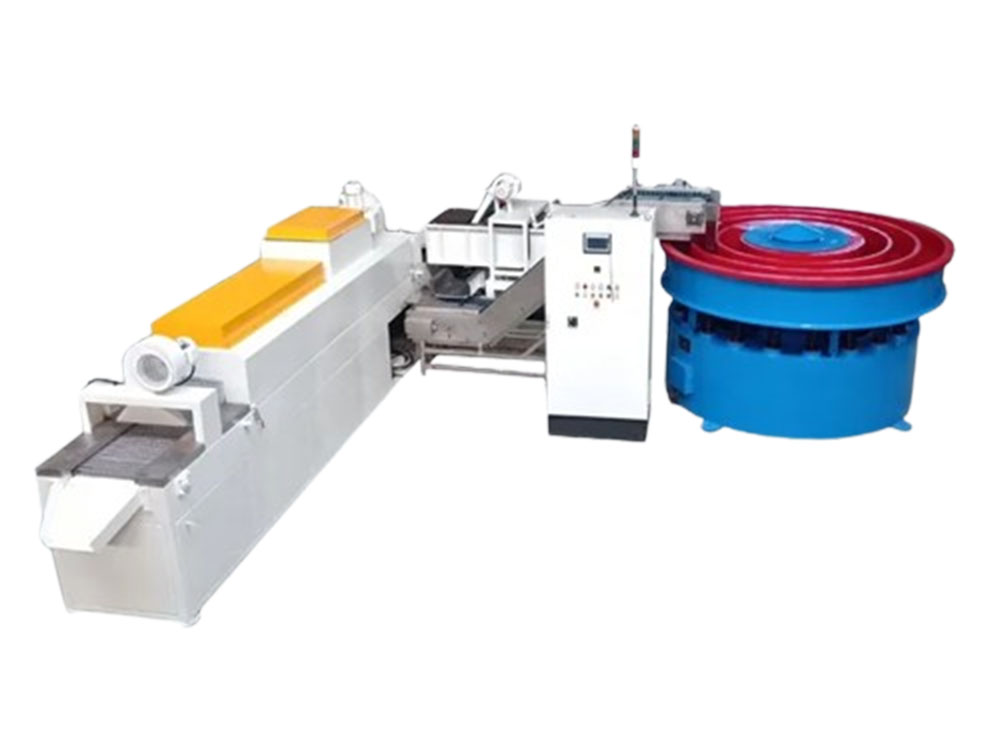

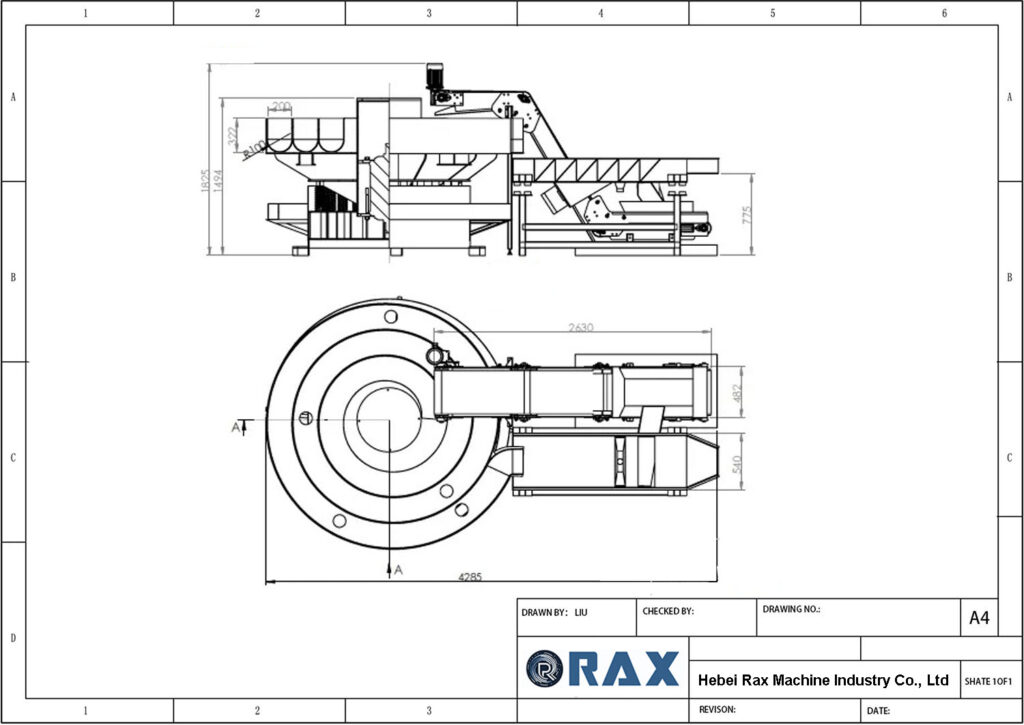

Rotomatic Continuous Flow Through System

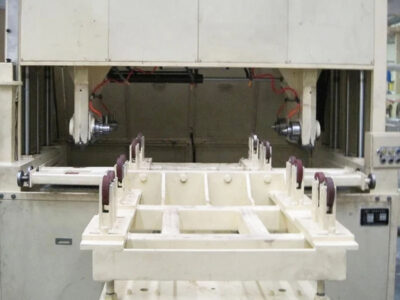

The rotomatic continuous flow through system deburrs, removes dust, rounds and polishes all forms of metals, non-ferrous metals and non-metal parts. After surface finishing, the shape accuracy of the state is not altered while surface roughness precision of parts is enhanced. The machine is an ideal solution for continuous industrial polishing and deburring of aluminium parts that minimises maintenance and labour costs while maintaining a high-quality finish. It is also called Automatic Sprial Vibratory Finishing Machine or Multi Channel Continuous Feed Vibratory System.

The machine works in a feed-in and feed-out manner and it is equipped with a rinsing station, dedicated media separators and lubrication system. On average, it takes around 15 minutes to process aluminium die-cast components. The primary advantages of the rotomatic continuous flow through system are increased productivity, minimal labour cost and maintenance, and consistent flow of production. It can be utilised in series of applications such as deburring and polishing aluminium die-cast parts, enhancing surface quality via controlled and consistent finishing, descaling metal parts as well as transporting and recycling media.